The treatment is often carried out using aqueous solutions of acids which decrease the vesicant activity of the liquid; alternatively, amine treatments can be used to reduce the concentration of cardol.

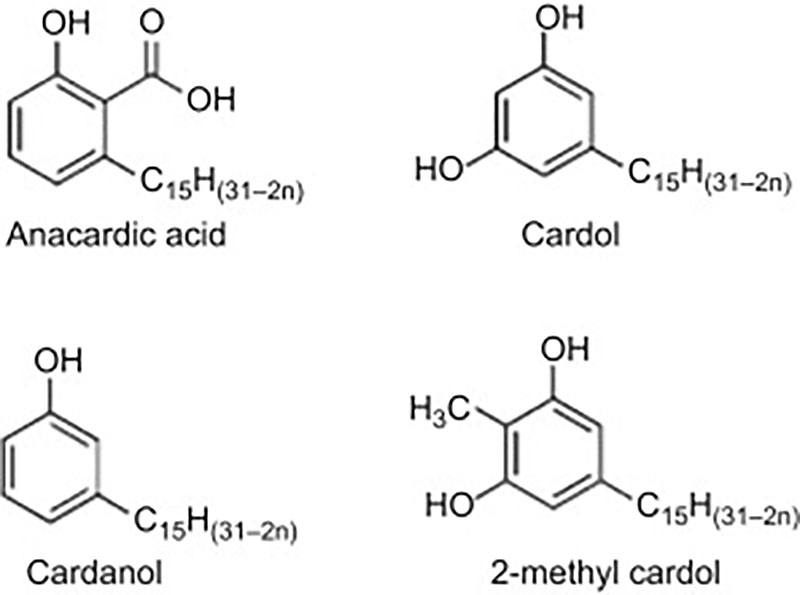

The main unsaturated phenolic substances in CNSL include anacardic acid (60–65%), 2-methyl cardol (1–2%), cardanol (10%), and cardol (15–20%). These ratios vary depending on the area and the cashew processing method used.

A bioeconomy-based economy is always an environmentally friendly response to regional and global pollution problems. The efficiency, simplicity, cost-effectiveness and environmental friendliness of CNSL-based technology have made it the answer to today’s sustainability problems.

The valorization of the CNSL has led to the creation of various products that compete with those obtained from fossil fuels. Furthermore, many of them are already in use and others are in development.

Four naturally occurring phenols make up CNSL: it has good possibilities as a substitute for commercial phenolics in several applications, with results at least as good. As raw material in azo compounds/dyes; friction linings; surface coatings, adhesives, paints; resins and rubbers; foundry chemicals; pesticides, larvicides and termite killers; pharmaceutical products; and biodiesel production, CNSL has a wide range of industrial applications.