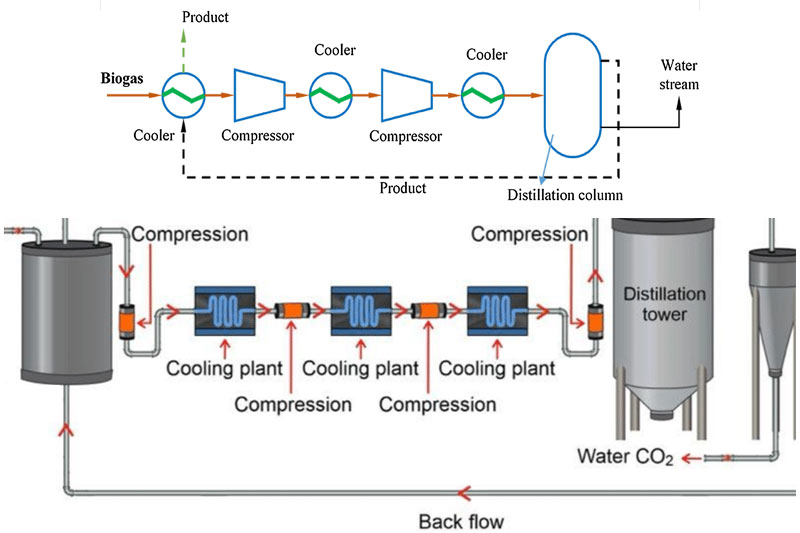

Cryogenic technology uses the boiling point of gases (CO2 ‐78 °C, CH4 ‐160 °C): the biogas is cooled to the point where the CO2 condenses and can be separated as a liquid.

This technology has a slightly higher application cost than the others, is energy intensive, but the purity of the gas is higher and requires significantly lower maintenance costs than other upgrade technologies also because no chemicals are used for biogas purification.

In combination with our heat to energy technology, which reduces the energy costs of both the scrubber dedicated to purification and the compressors used for cryogenic separation, it makes the adoption of cryogenics optimal compared to other technologies.