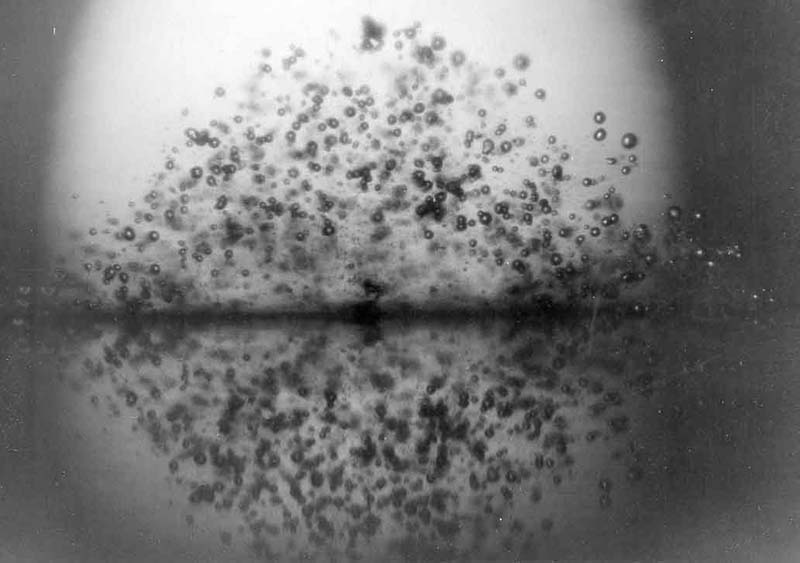

If in the liquid the absolute pressure becomes equal to or lower than the vapor pressure of the liquid at a certain temperature, in a few microseconds, microscopic vapor bubbles are formed.

This is because liquids normally carry air dissolved in them and when there is a drop-in pressure down to the vapor pressure value, the air dissolved in the liquid is released and, therefore, the vaporization of the liquid itself is released also. The steam bubbles are then dragged by the current and when they arrive in areas with a pressure higher than the vapor pressure, then the collapse of the bubbles occurs.

The collapse and implosion phase releases a quantity of energy which, if not controlled, can cause:

- a deterioration in the efficiency of the hydraulic system of at least 3%, due to the turbulence caused by cavitation.

- excessive vibration of the hydraulic system, causing noise.

- The severe deterioration of the internal components of the hydraulic system, due to the collapse of the bubbles near the wall of a component. In this case, a liquid jet (impinging jet) is generated which erodes the solid surface and forms what are called erosive pits. The area where this phenomenon occurs most frequently is at the impeller outlet, because in this section there is a temporary depressurization of the liquid, followed by a subsequent increase in pressure.

The erosion's degree is influenced by various factors, both related to the system's hydrodynamics and to the resistance behavior of the different materials.

The effects of condensation on the materials are mainly related to the surface hardness, the work hardening capacity and the grain size.

The cavitation erosion mechanism is very complex. In fact, in the literature, it is possible to find different theories on the causes of this process.

A first theory on the evolution of the erosive process provides that, when the single bubble implodes in a region of fluid away from the walls, its collapse occurs symmetrically. The surrounding fluid tends to quickly occupy the regions left free from the collapse of the bubble. This fluid movement induces a high intensity pressure wave that is transmitted quickly through the surrounding liquid. The high energy that is transmitted to the surrounding walls can lead to erosion of the material due to fatigue stress.