The reaction times are reduced to a few seconds and, at the same time, cavitation allows to treat any matrix, even if of a lower quality, obtaining extremely flattering and better levels.

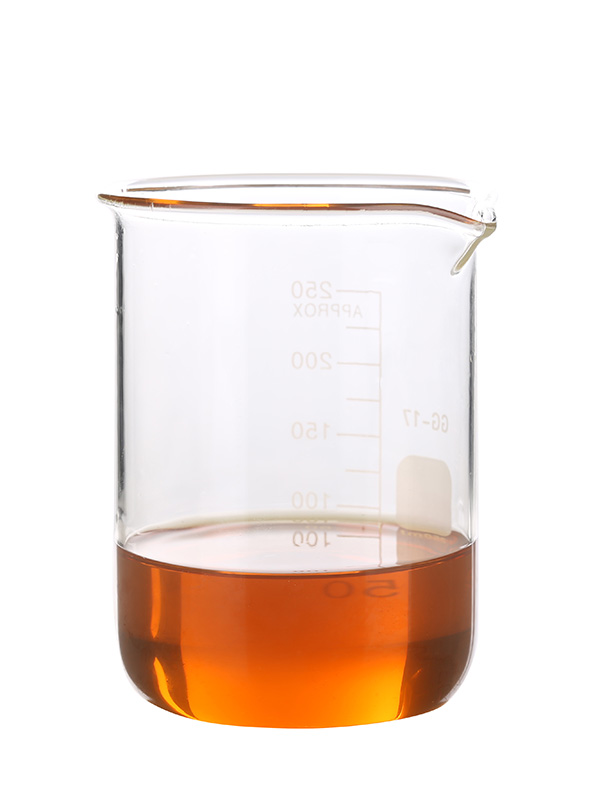

Biodiesel production begins by reacting the triglycerides with an alcohol and a catalyst. The products of this reaction are mainly biodiesel and glycerin.

Suffice it to say that the linked glycerin is less than 0.05% in biodiesel in two-stage systems.

Also in this case cavitation can be easily applied on existing plants in order to reduce costs and expand their production capacity or it can be the basis of totally innovative plants.

There are plants, especially in the United States, that have equipped themselves with this technology since 2005 and that use it with great profit despite the fact that the machines are those of the very first generations and therefore of the mono cavitation type without diffusion implementation for pressure recovery.

Using cavitation, production plants can use a greater quantity of matrices to be converted and with extremely higher values of free fats (FFAs). Therefore, used cooking oils, used oils from industrial processes, palm oils, beef tallow, poultry, etc. can be used as production matrices.

Furthermore, by speeding up the reactions, the quantities of catalysts to be used to complete the processes decrease accordingly.