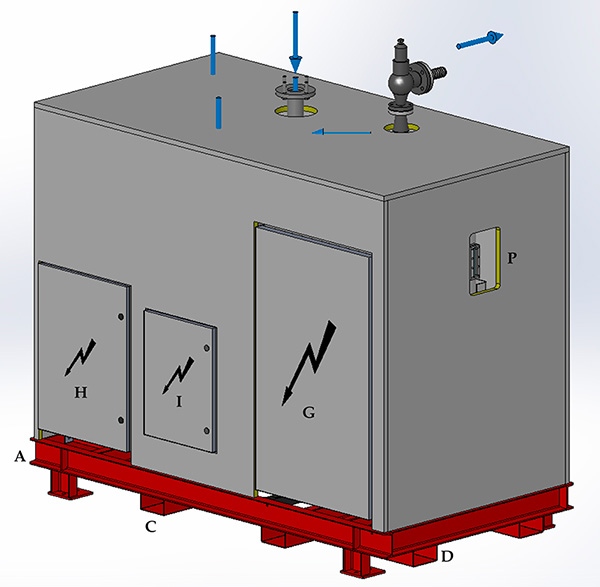

EMPOWERING DEVICE on its STANDARD version externally it looks like a parallelepiped 240 cm high, with a long side of 235 cm and a short side of 126 cm.

The metal basement (A) is 24 cm high and, thanks to a double system of overlapping and crossed mechanical guides (C & D) under the machine, it allows easy movement of the machine by forklift without any risk of accidental damage to the lower components. The air intake fans (U, V & W) are housed on the base.

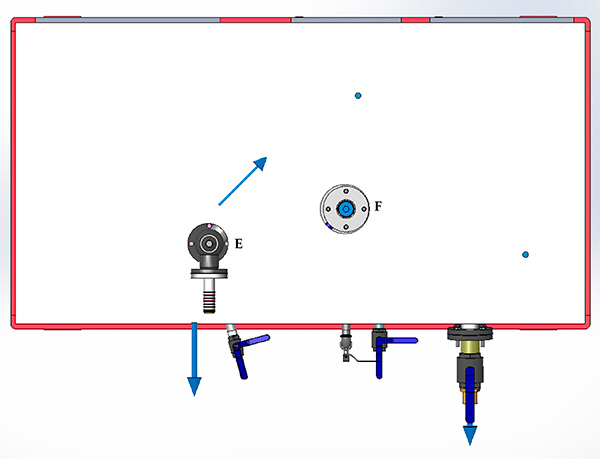

The safety valve (E - if present) and the inlet flange (F) protrude on the top.

On the first long side there are 2 doors: the electrical panel (G) and the compartment that houses the ozonators and the insufflator (H); optionally there can be the compartment that houses the chemical tanks (I) and a second electrical panel dedicated to the inverters (B).

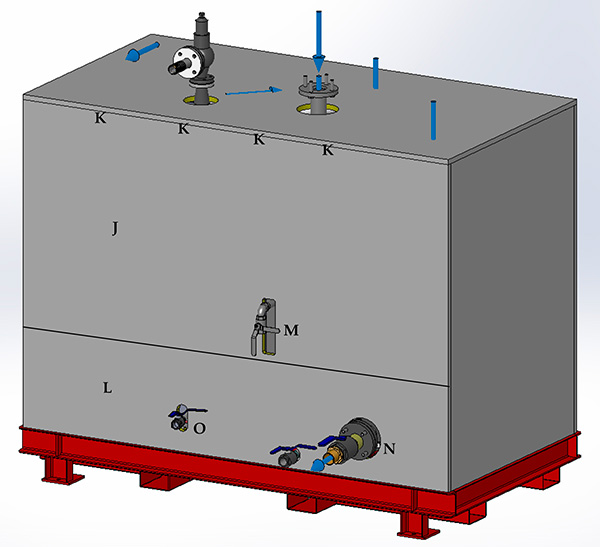

The second long side panel is split in half. The upper part (J) can be opened upwards thanks to some hinges (K) while the lower part (L) is occupied by 3 hydraulic connections: a tap for direct withdrawals from the tank (M), an outlet flange from the treatment (N), optionally equipped with a manual tap, and an emptying tap (O) of the residual waste remaining inside the body of the machine. The opening allows for easy inspection and routine maintenance, for example the grease refill of the bearings.

A door (P) opens on the first short side containing the sealing liquid tank.

The second short side is entirely dedicated to the machine identification plate (Q).

On the external sides there are 3 ventilation grids (R, S & T) that allow the air to escape.

The hood is made externally in high-density polyethylene while internally it is fully lined with fireproof and sound-absorbing material.

The bonnet, covered with this fireproof material, combined with the presence of valves and engines of the ATEX category makes it possible to classify the entire machinery within this category.

By replacing the internal tank with a rounded one, it is possible to push the entire machine up to 16 BAR after PED certification.

The EMPOWERING DEVICE is controlled by a PLC connected to a webserver and interfaced to the CLOUD via a 4G/5G modem, wired network or WI-FI or, optionally, satellite connection.

A GPS will allow the device to be geolocated anywhere in the world. Optionally, especially indicated and recommended for transportable models, the use of a generator is foreseen.